Internal Floating Roof

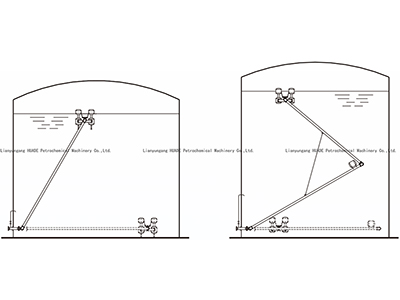

Internal floating roof is eco-friendly system that floats on the surface of liquid stored inside the storage tank. It rises or falls with the utilization of buoyancy, greatly yielding energy savings. This internal floating roof aims at controlling liquid volatilization, preventing energy loss, as well as minimizing environmental impacts. With the installation of the internal floating roof, the temperature inside the liquid storage tank decreases therefore resulting in less energy consumption and better environmental protection.

| Structure Type | Pontoon type internal floating roof |

| Liquid Medium | Oil, chemicals and volatile liquids |

| Storage Tank Diameter | 3m ~60m |

| Material | Aluminum alloy, stainless steel |

| Seal Type | Single layer wiper seal, single layer foam seal, double layer seal |

| Seal material | Nitrile rubber (NBR), EPDM, PTFE, fluorine rubber |

| Tank working pressure | Positive pressure: 1961Pa Negative pressure: 490Pa |

| Energy consumption reduction | ≥95% |

| Buoyancy | Supporting at least twice the dead weight of floating roof |

| Pontoon diameter | Aluminum pontoon: 185mm Steel pontoon: 260mm |

| Floating Roof Height | 1700mm~1800mm |

| Lifespan | 15 years under normal operation |

| Rim space (area between internal floating roof and tank shell) | 50±20mm |

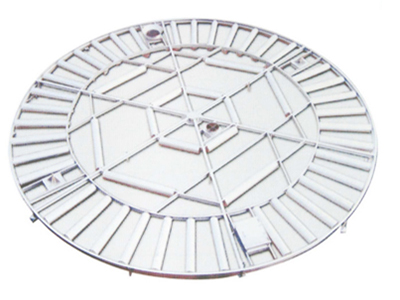

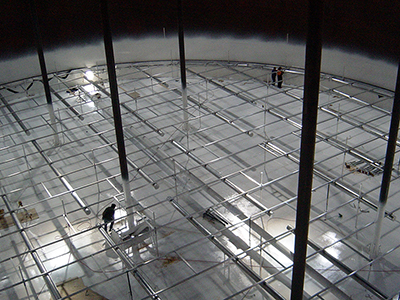

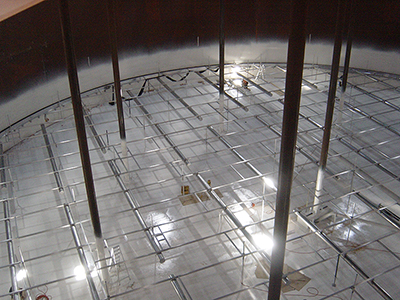

- Unique Hexagonal Structure

This newly developed internal floating roof features a spider web-like hexagonal structure that offers higher structural strength and more stability in comparison with conventional structure with same weight of materials. Thanks to the damping property of the hexagonal structure, the shock wave will be efficiently reduced. - Reasonable Pontoons Arrangement

Because smaller size pontoons are utilized, this internal floating roof has more quantities of pontoons that are distributed reasonably and uniformly. The intensive layout of pontoons effectively avoids issues of floating roof tilting, significantly improving operation stability.

Since the pontoon has a smaller size, the gap between pontoons and floating roof deck is reduced therefore resulting in a good damping effect to absorb the upward force and shock when the floating roof in motion. - Superior Aluminum Pontoons

The pontoons of the internal floating roof are made of seamless aluminum pipe, greatly reducing the risk of leakage. - High Energy Efficiency

The structure design of the internal floating roof helps reduce evaporation of the stored medium of over 98%, ensuring a safe operation with minimal environmental impact. - High Utilization Rate of Storage Tank

Due to its small liquid-gas space which is less than 90mm throughout its full thickness of 300mm, this internal floating roof allows for more storage volume compared to other types of floating roof. - Simple Installation, Low Maintenance Cost

This internal floating roof can be quickly installed with bolts, eliminating the need for welding, enabling it particularly suitable for retrofitted tanks. The main parts are made with standard molds, ensuring good interchangeability and versatility. - Guaranteed Safety Performance

Electrostatic discharge is based on a standardized control, resulting in no potential electrostatic hazards and no need to weld, thus ensuring the safe operation of floating roof.

HUADE has focused on designing and producing fluid loading arms for the transfer of liquids and gases since its inception in 1991. As an experienced loading arm manufacturer, we believe that safety and efficiency are the two most important criteria which ultimately matters to our customers. All of our liquid loading systems and fluid handling equipment are manufactured to international standards, and tailored to different application needs. Regardless of marine, road and railway liquid transfer systems, our engineers always strive for continuous innovation, development and improvement for the satisfaction of our customers in chemical, petrochemical, pharmaceutical, beverage, and other industries.