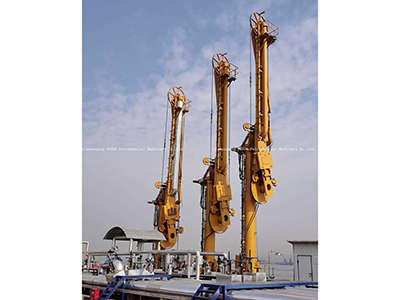

Marine Loading Arm (Manual Operation)

Operating method: manually operated

Supporting structure: independent support, hybrid support, self support, single or double arm

Marine loading arms for manual operations are typically used for transporting fluid between pipelines of inland rivers and small seaports and tankers. During the process of fluid transfer, the design of the loading arm allows it to accommodate the drift and movement of the tanker or ship within its predetermined range without damaging the equipment. In order to prevent drifting past the design range, a range alarm system can be installed to trigger audible and visual warnings to alert operators of excessive drift. Manual arms are lighter, less costly, and require less maintenance than their hydraulic counterparts.

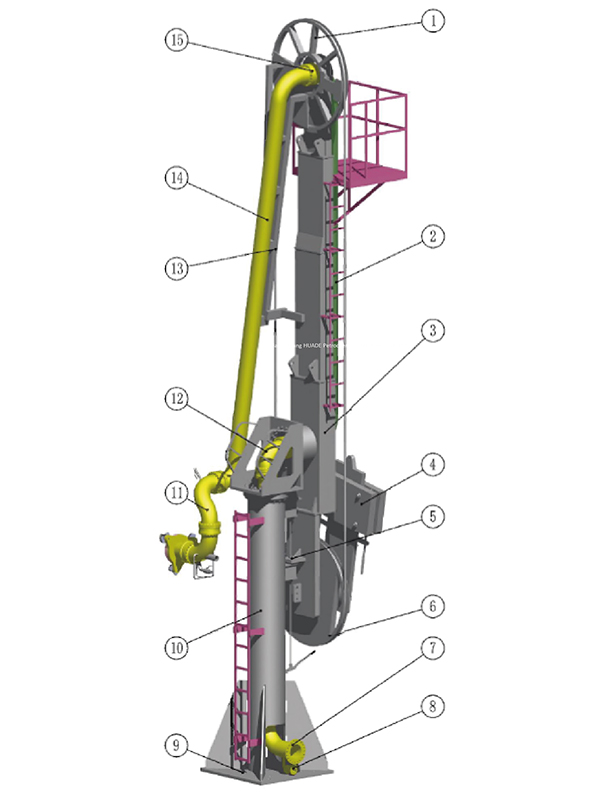

- Apex Sheave

- Inboard Arm

- Inboard Arm Support

- Counterweight

- Locking Device

- Cable Sheave

- Connection Flange

- Drain Nozzle

- Base Plate

- Riser

- Triple Swivel Assembly

- Removable Elbow

- Outboard Arm Support

- Outboard Arm

- Apex Swivel Joint

- Nominal diameter: DN80-DN250 (3”-10”)

- Design pressure: -0.6~10MPa

- Design temperature: -50℃~+250℃

- Pipeline material: carbon steel/stainless steel/PTFE lined

- low-temperature carbon steel

- Explosion-proof grade: ExdII BT4, Protection grade: IP65

- Manual quick connect-disconnect coupler (QCDC)

- Heat tracing and insulation

- Range alarm system

- OCIMF: Design and Construction Specification for MLA

HUADE has focused on designing and producing fluid loading arms for the transfer of liquids and gases since its inception in 1991. As an experienced loading arm manufacturer, we believe that safety and efficiency are the two most important criteria which ultimately matters to our customers. All of our liquid loading systems and fluid handling equipment are manufactured to international standards, and tailored to different application needs. Regardless of marine, road and railway liquid transfer systems, our engineers always strive for continuous innovation, development and improvement for the satisfaction of our customers in chemical, petrochemical, pharmaceutical, beverage, and other industries.